Surrounding the entire personnel, whole process and the overall life cycle to build a quality standard satisfied by customers.

Quality principle: Produce quality goods with diligence and serve with sincerity

Quality philosophy: Quality first, responsibility first, improvement first

The GAC NE intelligent ecological plant broke ground in September 2017 and has a gross investment of RMB 4.7 billion, a floor area of 470,000 square meters, an overall planned production capacity of 400,000 vehicles per annum, and a first-phase production capacity of 200,000 cars per annum. This plant is a world-class digital intelligent plant featuring the Internet of Things, big data, and customization, an innovative plant for comprehensive energy utilization with a smart micro-grid, photovoltaic and other clean energy sources, and an electric energy storage system, and a future-oriented world-class new-type intelligent and connected model plant that represents the new levels of smart manufacturing, quality, customization and environmental protection of GAC.

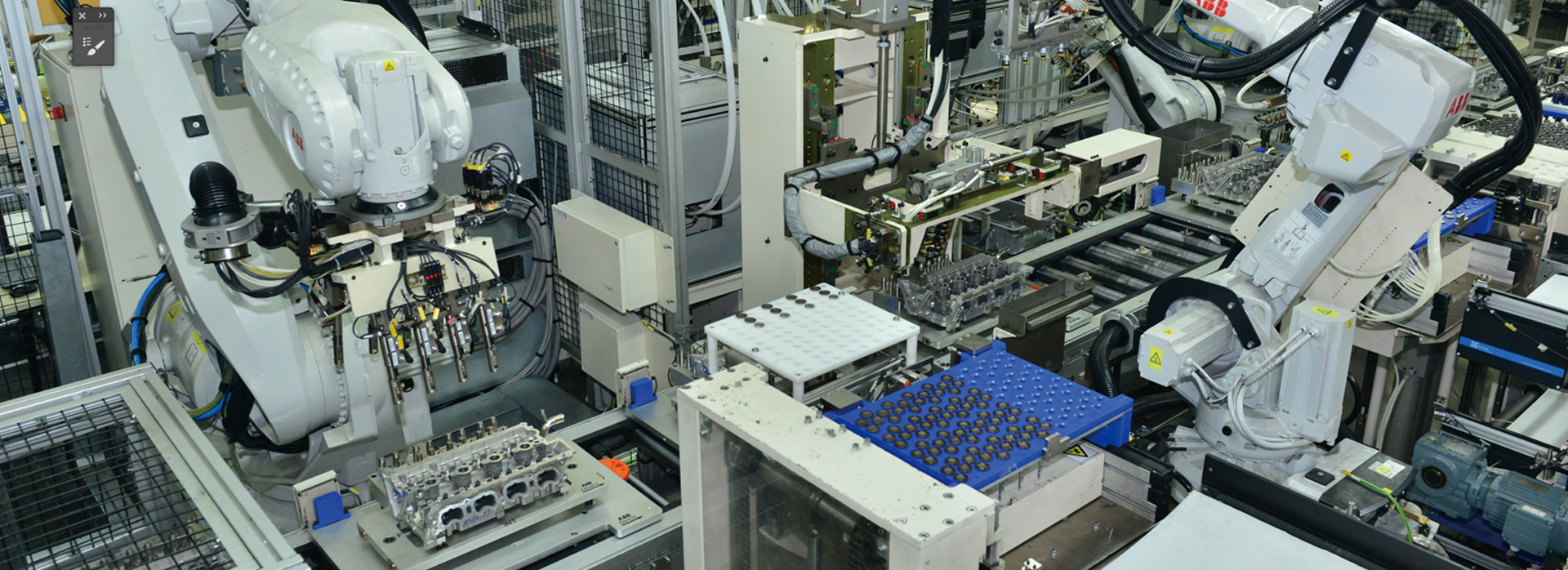

The GAC NE intelligent ecological plant is the first in the world to use aluminum riveting and spot welding changeover technology, has a “steel-aluminum hybrid” production line, and makes better-quality and safer lightweight vehicle bodies in response to the application of lightweight materials (e.g., aluminum alloys) in the future. The GAC NE Aion S uses a hybrid vehicle body with high-strength steel and an aluminum alloy lower body to realize world-class safety and lightness, and maximum occupant protection.

The GAC NE intelligent ecological plant is the first domestic vehicle plant that uses a global data cloud platform for production process analysis and decision-making to improve production efficiency and quality control capacity greatly, and to make the best products. Intelligent manufacturing gives machines human wisdom, and realizes data acquisition, analysis, judgment and decision-making.

Through the C2B customization of intelligent vehicle manufacturing, the GAC NE intelligent ecological plant is the first of its kind in the world that involves users deeply in vehicle design and manufacturing, provides them with individualized experiences, and makes exclusive vehicles. Users can enjoy rich, interactive and interesting smooth individualized experiences through the GAC NE app. For example, 16,800 and 60,000 solutions can be customized for the Aion S and the Aion LX respectively. Through the app, users can see the production process of customized models at any time, and witness the birth of their own vehicles, which can enhance the participation and sense of ritual of users in the production process.

The GAC NE intelligent ecological plant is the world’s first plant that utilizes energy comprehensively. It also applies green technologies and materials comprehensively to harmonize with the environment and realize sustainable development. The new plant uses 52,000 photovoltaic panels (85,000 square meters) to build a solar roof that generates 16.77 million kWh of electricity annually, accounting for about 15% of the plant’s full-load power consumption; a power battery energy storage yard has been built to store surplus electricity, with a first-phase storage capacity of 1,000 kWh. Advanced environmental technologies are used extensively in the new plant. For example, the liquid damping material spraying technology used at the painting shop sprays the aqueous green material LASD fully automatically, reducing benzene and aldehyde VOCs in vehicles by 49%, and the advanced green film technology (hydrozirconation) realizes the zero emission of harmful substances.